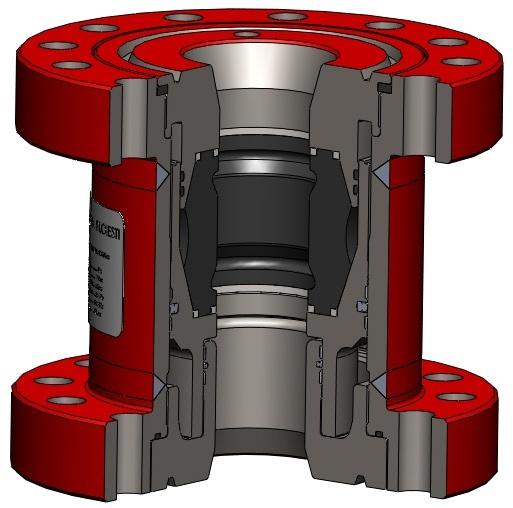

Stripper (figure 1) is an equipment that completes blowout prevention systems. It prevent the escape of oil or gas while running or pulling tubing under pressure.

|

| Figure 1 |

It’s special rubber packer allows easy passage of tubing and tubing couplings without leakage. Stripper features a hydraulic actuator which allows the stripper rubber to be compressed quickly and safely without stopping operations. Stripper actuating pressure is 35÷70 bar.

Stripper can be operated using:

- CH6U-3000 psi control unit, or

- handpump.

SPECIFICATIONS

| Stripper type | SH 7 1/16 x 210 / 70 bar |

| Section | Ø102 mm (4 in) |

| Static working pressure | 70 bar (rest of the tubing) |

| Body testing pressure | 140 bar |

| Stripping sealing pressure | min. 35 bar (translational state of the tubing) |

| Flanged connections | 7 1/16 x 210 |

| Tubing size | 2 3/8 – 2 7/8 in |

| Hole sizes for connection to hydraulic control system | Rc 3/8 in |

| Piston closure race | cca.32 mm |

| Total Oil volume for total piston stroke | 2 litri |

| Actuation | hidraulic |

| Overall dimensions : maximun diameter | Ø 380 mm |

| height | 300 mm |

| Weight | 138,5 Kg |

|

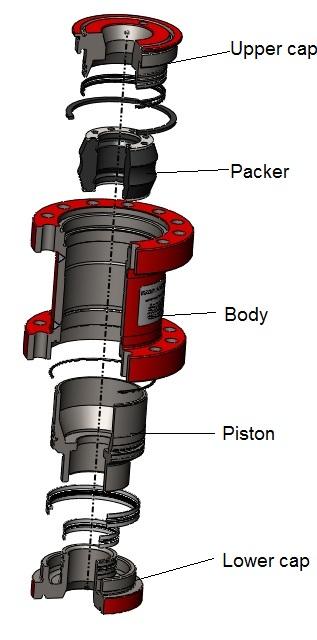

This main parts are shown in figure 2 |

|

||

| Figure 2 |

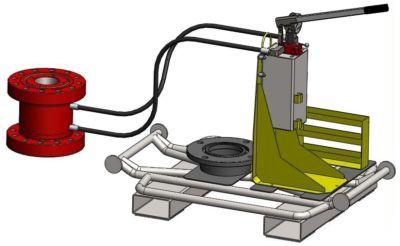

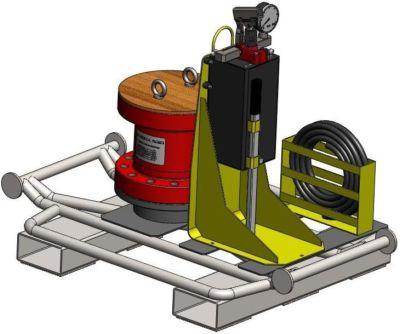

| Handpump hydraulic actuating system (figure 3) consists of: | |

|

- PAM-TDS 45 handpump - 10 liters tank - hydraulic hoses (Dn 10 x 350 bar – 4 m ) |

|

|

|

| Figure 3 | |